[Today’s run: 8 miles with Boardtown Runners]

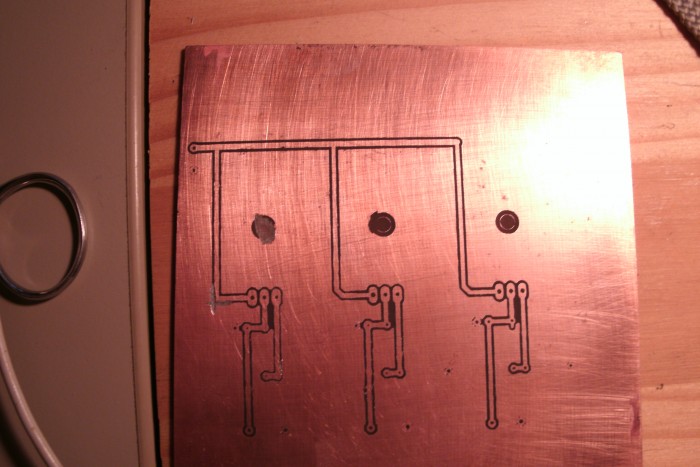

I have had mixed success with home-made circuit boards.

I have a laser printer and I have some free layout software called Eagle Cad. I have been able to make three boards so far, all of them simple.

I use the laser/iron method which you can find on the googleplex. The gist of it is that you print your board “resist” pattern on slick paper, like from a magazine or the cover of one of these clothing catalogs that my wife gets in the mail all the time. You then transfer the printed pattern to copper circuit board material using a hot clothing iron. After that you soak in water and rub off the paper to leave just the laserjet toner, now on the circuit board.

Then you use an etching chemical to remove the copper from the circuit board in all the places where copper is showing.

The board in the picture is wrapped up in black vinyl electrical tape everywhere except in the printed area, so it saves the copper on the whole board except for the traces . (This type of board material has copper on both sides.)  I am swishing it around in ferric cloride which I purchased at an electronics store. You have to use a plastic or glass container.

I am swishing it around in ferric cloride which I purchased at an electronics store. You have to use a plastic or glass container.

After the etching I rinsed the board to stop the etching action. Then I unwrapped all of the electrical tape. I used spray carburetor cleaner to clean off all of the laserjet toner and tape goop. Acetone is supposed to work, but I don’t have any at the moment.

My board turned out pretty good. I had to touch up a couple of areas with my Dremel tool. I think my traces are a bit messy. I don’t know if that is the type of paper I’m using or some fault in my ironing. They say if you iron too much it will mush the toner around a bit, so maybe that is my problem.